Project Description

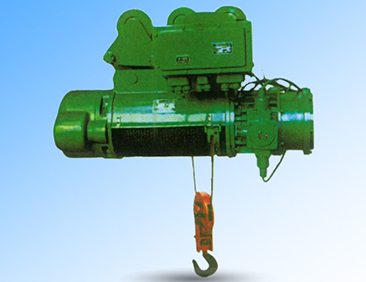

HHEX Explosion-proof Electric Hoist

| Lifting Capacity | 0.5-16t |

| Lifting Height | 6-18m |

| Working Class | M3 |

| Ambient Temperature | -25-40℃ |

Overviews

Applications

Explosion proof electric hoist can be used on the main I-beam track to run in straight or curve line to handle materials or installed on a fixed bracket as a lifting solution for heavy loads. Explosion- proof electric hoist also can be fixed to different applications, working with explosion proof single girder overhead travelling crane or with the explosion proof dual beam bridge crane, etc.

Advantages

- Compact structure, small size, light weight, large capacity.

- High safety and reliability.

- All the spare parts are generalized and changeable, which make hoist maintenance easy and simple.

- No spark materials are used to the outside parts enhancing anti-explosion ability of electric hoist.

- Explosion proof electric hoist is designed and manufactured according to GB3836-2000.

Features

- Lifting motor used in explosion proof hoist is fully closed tapered rotor asynchronous motor of explosion-proof motor series.

- Max torque of lifting motor is 2-3 times of full loading, ensuring the safety and reliability of explosion proof hoist.

- The lifting motor has the insulation class of B or F and the protection class is IP44/IP54.

- Explosion proof hoist adopts standardized modulus of cylindrical gears, installed with antifriction bearing, which is convenient to maintenance.

- High strength gear and gear shaft are made from heat treated alloy steel.

- Lifting reducer shell is made of high quality cast iron which is closely assembled and is dust proof.

- The lifting reducer can work reliably and high efficiency.

- The hook of explosion proof electric hoist is made of high quality carbon steel, supported in the hook beam through a single scroll thrust bearing, free oscillation.

- Hook for 5t and below loads is single slippery wheel whereas hook for 10t or heavier loads is double slide wheel.

- Explosion proof hoist use hooks with card board type structure at hook end.

- When explosion proof hoist is applied to application of explosion –proof dllCT4, the hood head will be made from stainless steel.

- Protection devices are adopted, such as, up and down traveling limiter, overloading limiter, and anti-clashing devices, etc.

- Explosion proof electric hoist can be operated through wire rope control and remote control. The explosion proof switch is safe and reliable.